- About us

- Contact Us

- Site map

- Language:中文English

Nowadays, UV printers can directly print desired patterns on various materials, with rich colors and no need for plate making. The printing effect is fine and environmentally friendly, which can replace traditional printing processes. In the advertising industry, it can produce signs, signs, posters, display boards, signs, acrylic lightboxes, PVC lightboxes, high-end business cards, etc. Large to large plaques and signs, large display advertisements, outdoor spray painting, as well as business cards, advertising gifts, medals, medals, badges, badges, etc., can all be printed. At the same time, they are widely used in indoor home decoration, building materials decoration, colored crystal glass, metal sheets, wooden doors, ceiling ceilings, home appliance panels, digital toys, and other fields. So what are the specific advantages of UV printers? Mingke UVs will be explained one by one to everyone.

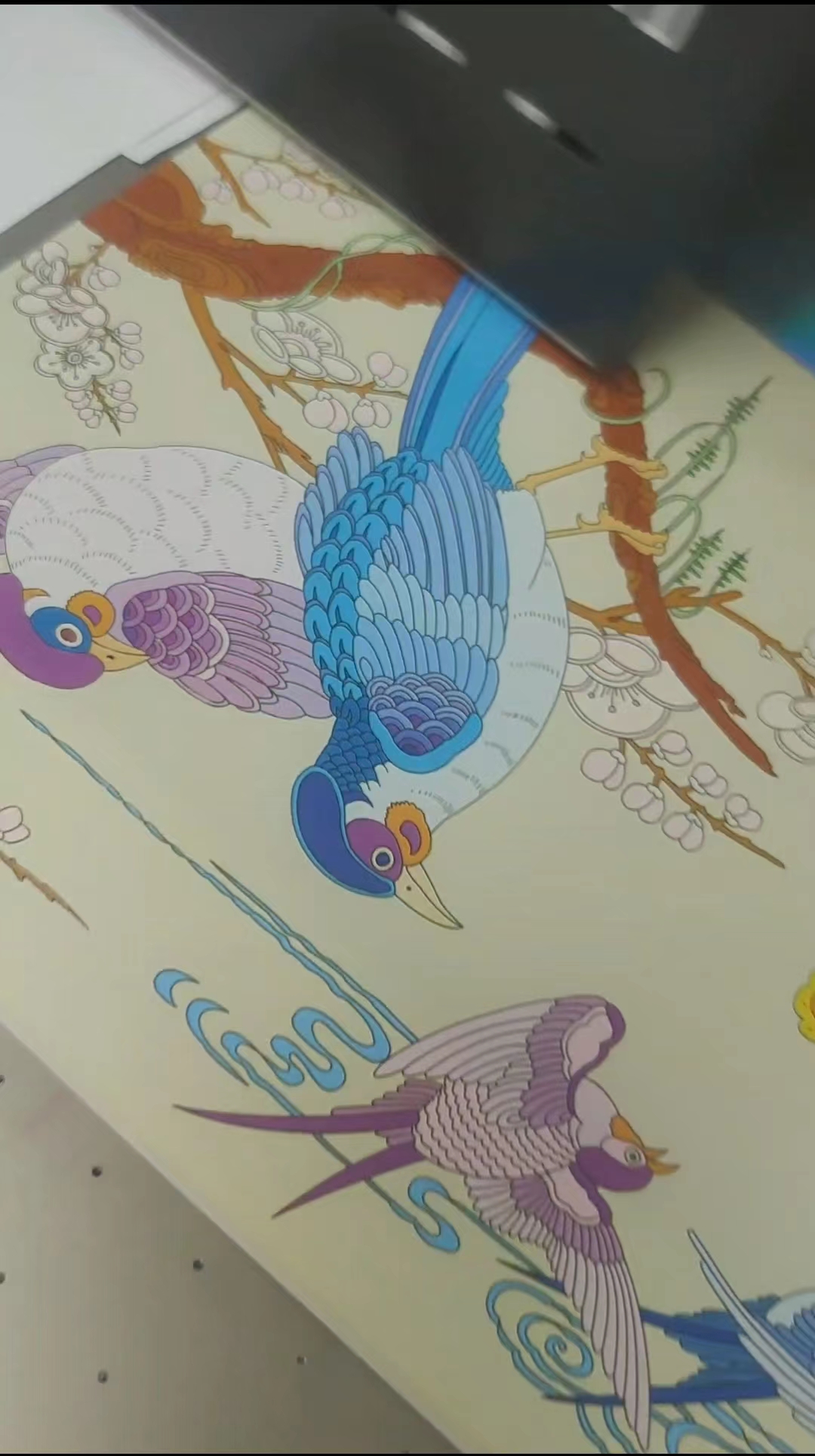

Craft decorative paintings

1、 More advanced printing methods:

UV printers can print full-color patterns all at once, and gradient colors can also achieve photo level effects. They have precise positioning during printing, zero scrap rate, and save a lot of manpower, material resources, and financial resources. In the traditional printing field, two very tricky problems often encountered are image alignment and color calibration. Even skilled employees cannot fully achieve 100% accuracy in alignment and color calibration, which inevitably leads to position deviation and color difference in work, easily causing significant waste. However, UV printers can adjust the color of the image on the computer, and then control it through digital software to accurately align the area and position to be printed, printing colorful patterns without color difference, which traditional printing cannot achieve. UV printers can achieve true plate less printing in production, with the cost of single sheet printing and batch processing being similar. They can efficiently and economically complete small batch products, helping users increase more business opportunities and printing profits.

2、 Printing products for more personalization:

UV printers can meet people's personalized needs. For designers, they can fully utilize their creative talents. Design samples can be freely modified on the computer, and the effect on the computer is the finished product. If customers are satisfied, they can directly complete the production. The patterns printed by UV printers are very fine, capable of printing 3D effects, with rich and clear pattern layers; Capable of printing relief effects with strong three-dimensional sense; Capable of printing partial or full gloss effects, with pattern colors that do not fade for a long time while also possessing artistic qualities; The ability to print patterns in photography and painting styles has great potential for application in industries such as advertising and decoration.

3、 Print products for more yuan:

The materials that UV printers can print are very diverse, making the products that can be printed very diverse. Regardless of the industry, any product that wants to print patterns on the outer surface can be applied to UV printers, whether it is hard or soft materials. Hard media such as glass, various metals, ceramic tiles, wooden boards, acrylic boards, chevron boards, corrugated cardboard, plastic boards, resin boards, gypsum boards, KT boards, etc; Flexible media such as car stickers, reflective films, oil canvas, carpets, leather, etc. can all be printed. More and more people are using UV printers in the field of industrial handicrafts, such as phone cases, cosmetics, keyboards, yoga mats, carpets, stationery, and other industries. Through innovation and improved processes, new products are developed to enhance product recognition, increase differentiation, and bring customers a better visual experience and rich color effects, thus making a lot of money.

WeChat customer service

WeChat customer service